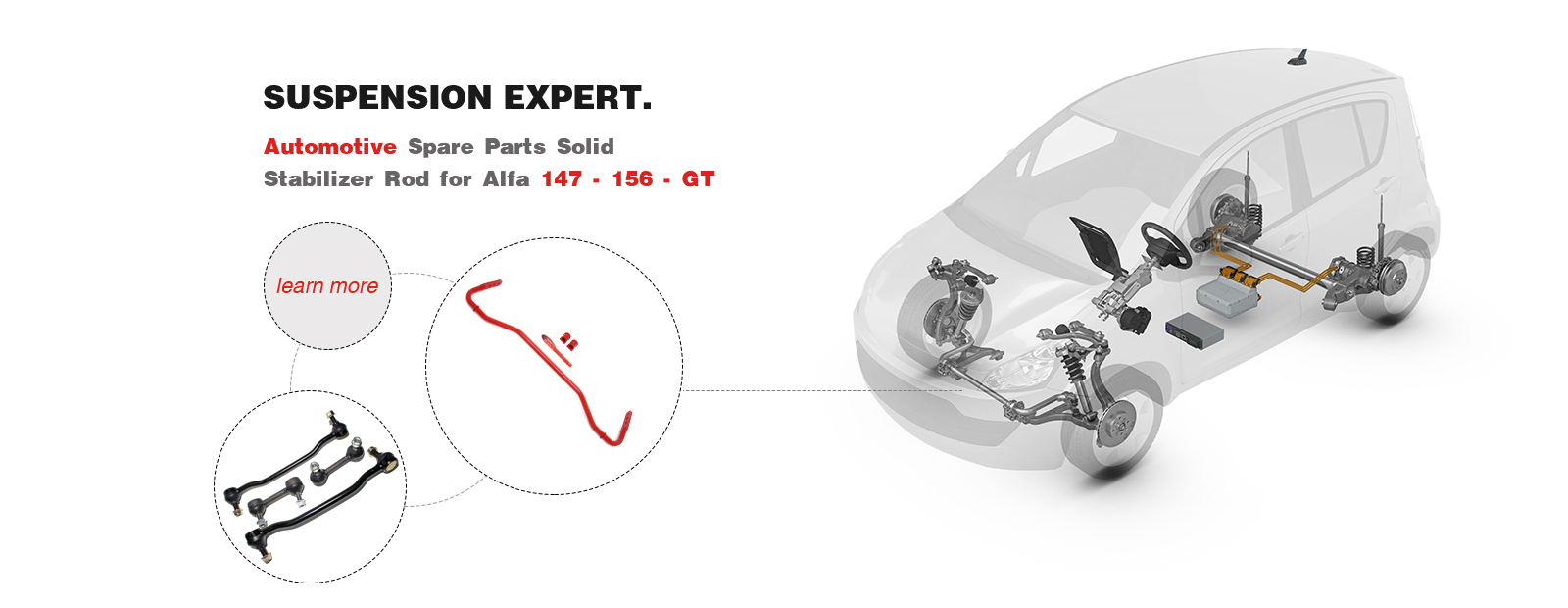

How to choose the right sway bar for your car make?

Get In Touch

Mobile:86-13736677602

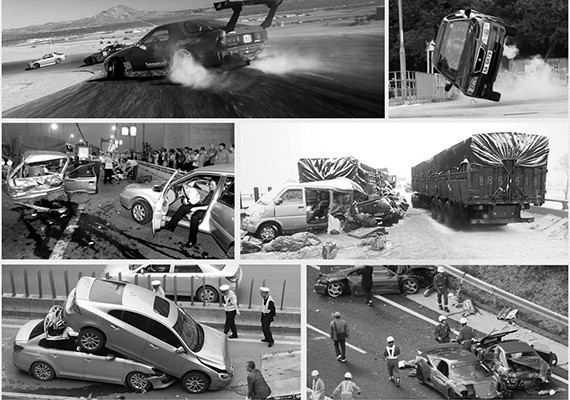

90% cars are installed with sway bar.

60% car owners will choose high-quality sway bar.

40% cars are with the risk of sway bar fracturing in driving.

10% cars are taking the risks of slipping, overturning and casualties.

Internationalized Standard Factory & Full Sets Production Lines

YZS moved to the new site in April 2019 with new equipment invested, the production capacity will expanded to a new stage.

Accurate Engagement in Target Market

Based on 20 years professional experience, we are familiar with not only the traditional OEM customers, but also the emerging performance car market. According to different customer requirements and demands (domestic or abroad), we can serve them with our most proper and accurate plan and satisfy their market needs.

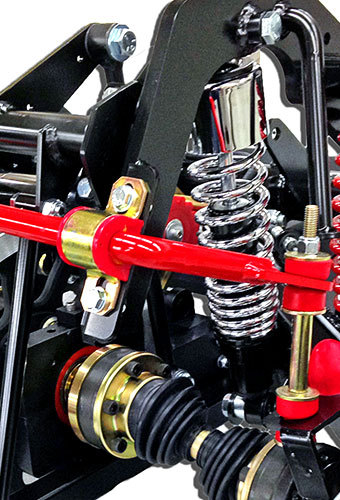

High Standard Quality Control System

YZS equipped with the most advanced production lines and the best testing laboratory. We are rigorous on quality control.Raw material incoming checking, high precision fixtures and modules using, and process inspection are our key control methods.

Cooperated with Well-known Brands

YZS has cooperated with many well-known enterprises in after-market and performance car field and sold its products to more than 40 countries.

Professional Core Operation Team

Core operation team was established in 2005. Since then we reformed our system and introduced the advanced management to the company. After years hard-working, now we have build a team with clear hierarchy, experienced, skillful, stable and ambitious team.

Small Orders, Customized and Fast Production

Small orders, customized and fast production are the tendency of our industry. In order to match it, we timely revised our MOQ and imported ERP system to support our production management

Pre-sale

- ◆

- Sample confirmation: YZS can supply sample for confirmation. By it, customers can make sure if the product is correct and also have direct impression on our quality.

- ◆

- Set safety stock for hot sales products. It will greatly shorten the lead time and satisfy customer’s expectation.

Sale

- ◆

- Put Q&A column for answering general questions

- ◆

- Standardized the answers to all kinds of questions. Make sure customers only replied in one unified answer from different staff.

After-sales

- ◆

- Weekly update production status and share with customers. Timely inform customers once his orders are delivered

- ◆

- Timely follow-up the sales status and feedback in customer local market. Generally we collect the information in one month after customers receiving the goods.

- ◆

- Sending product and its packaging pictures for your confirmation.

New products will inform you at regular intervals.

- ◆

- 24 hours online service